The Equipment Ranking Method

Equipment Criticality Analysis

Every Maintenance Organization must have a comprehensive equipment register ranked for criticality, this is an absolute requirement for an effective maintenance strategy. There are many ways a Maintenance Organization has attempted this with various levels of effectiveness, but major drawback of each of these attempts is stopping at the machine level. An effective maintenance strategy must be established at the component level. This is where the appropriate maintenance task is selected to reduce equipment downtime thus improving OEE.

An Equipment Criticality Analysis process expands traditional Equipment Ranking processes to include ranking individual components on critical equipment. This allows an Equipment Ranking Team to select an appropriate maintenance task for the component. When the ranking analysis is completed, and a comprehensive list of maintenance tasks have been identified including Predictive, Preventive, Failure Finding and Consequence Reduction Tasks.

Benefits of an Equipment Ranking Method Course

- Learn how develop a complete Maintenance Strategy for your equipment

- Learn where to apply predictive and preventive maintenance tasks

- Improved Manufacturing and Equipment Reliability

- Reduce Maintenance Costs

- Reduce Unit Cost of Finished Product

- Reduction in Health, Safety and Environmental Incidents

Who should attend this course?

- Maintenance Managers and First Line Supervisors

- Operations Managers

- Engineering Managers, as well as Mechanical, Electrical, and Chemical Engineers

- Senior Trades, Leads, and Planners

Those who attend the Equipment Ranking Course training will receive:

- A Course Manual

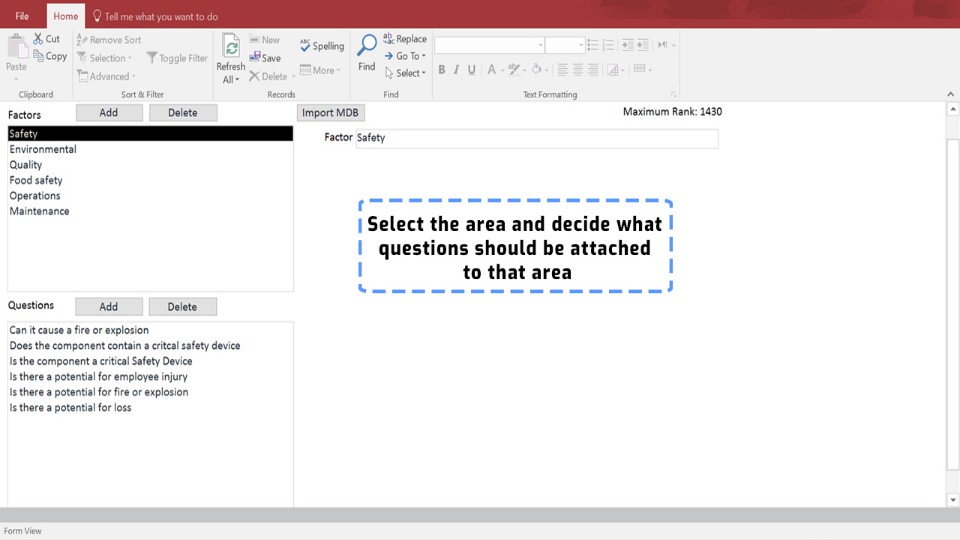

- Equipment Ranking Database Discount (sample screenshot below)

- Equipment Ranking Participant manual

- A Certificate of Course Completion

The Asset Criticality Software was developed with guidance from Reliable Process Solutions, to learn more about this software or for purchasing separately without training please visit here:

Asset Criticality Software 2.0